Casting is a manufacturing process wherein molten metal or other materials are poured into a mold and allowed to solidify. This creates a three-dimensional object with the desired shape and properties. It is widely used for producing complex metal components in the automotive, aerospace, construction, and medical industries.

Working with the right casting manufacturer can affect the component quality, performance, cost, and timely delivery. An unqualified partner may lack the expertise, knowledge, and experience to produce high-quality results. This can lead to product failures, increased rejection rates, safety risks, and additional costs and delays.

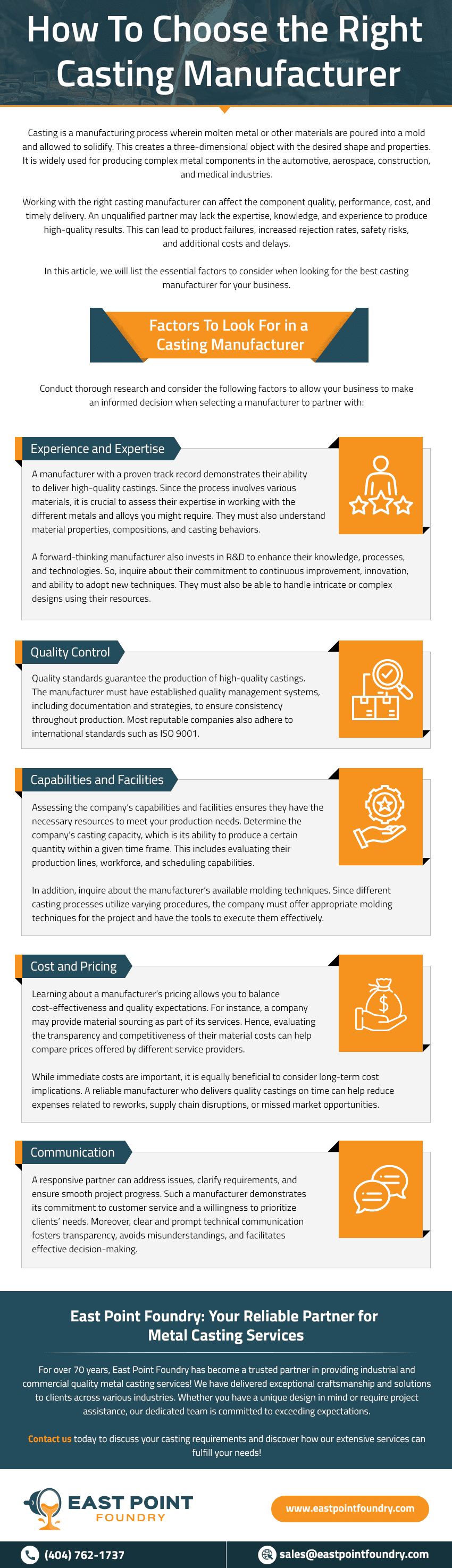

In this article, we will list the essential factors to consider when looking for the best casting manufacturer for your business.

Factors To Look For in a Casting Manufacturer

Conduct thorough research and consider the following factors to allow your business to make an informed decision when selecting a manufacturer to partner with:

Experience and Expertise

A manufacturer with a proven track record demonstrates their ability to deliver high-quality castings. Since the process involves various materials, it is crucial to assess their expertise in working with the different metals and alloys you might require. They must also understand material properties, compositions, and casting behaviors.

A forward-thinking manufacturer also invests in R&D to enhance their knowledge, processes, and technologies. So, inquire about their commitment to continuous improvement, innovation, and ability to adopt new techniques. They must also be able to handle intricate or complex designs using their resources.

Quality Control

Quality standards guarantee the production of high-quality castings. The manufacturer must have established quality management systems, including documentation and strategies, to ensure consistency throughout production. Most reputable companies also adhere to international standards such as ISO 9001.

Capabilities and Facilities

Assessing the company’s capabilities and facilities ensures they have the necessary resources to meet your production needs. Determine the company’s casting capacity, which is its ability to produce a certain quantity within a given time frame. This includes evaluating their production lines, workforce, and scheduling capabilities.

In addition, inquire about the manufacturer’s available molding techniques. Since different casting processes utilize varying procedures, the company must offer appropriate molding techniques for the project and have the tools to execute them effectively.

Cost and Pricing

Learning about a manufacturer’s pricing allows you to balance cost-effectiveness and quality expectations. For instance, a company may provide material sourcing as part of its services. Hence, evaluating the transparency and competitiveness of their material costs can help compare prices offered by different service providers.

While immediate costs are important, it is equally beneficial to consider long-term cost implications. A reliable manufacturer who delivers quality castings on time can help reduce expenses related to reworks, supply chain disruptions, or missed market opportunities.

Communication

A responsive partner can address issues, clarify requirements, and ensure smooth project progress. Such a manufacturer demonstrates its commitment to customer service and a willingness to prioritize clients’ needs. Moreover, clear and prompt technical communication fosters transparency, avoids misunderstandings, and facilitates effective decision-making.

East Point Foundry: Your Reliable Partner for Metal Casting Services

For over 70 years, East Point Foundry has become a trusted partner in providing industrial and commercial quality metal casting services! We have delivered exceptional craftsmanship and solutions to clients across various industries. Whether you have a unique design in mind or require project assistance, our dedicated team is committed to exceeding expectations.

Contact us today to discuss your casting requirements and discover how our extensive services can fulfill your needs!

Recent Comments